Product Category

Sensors Electronics

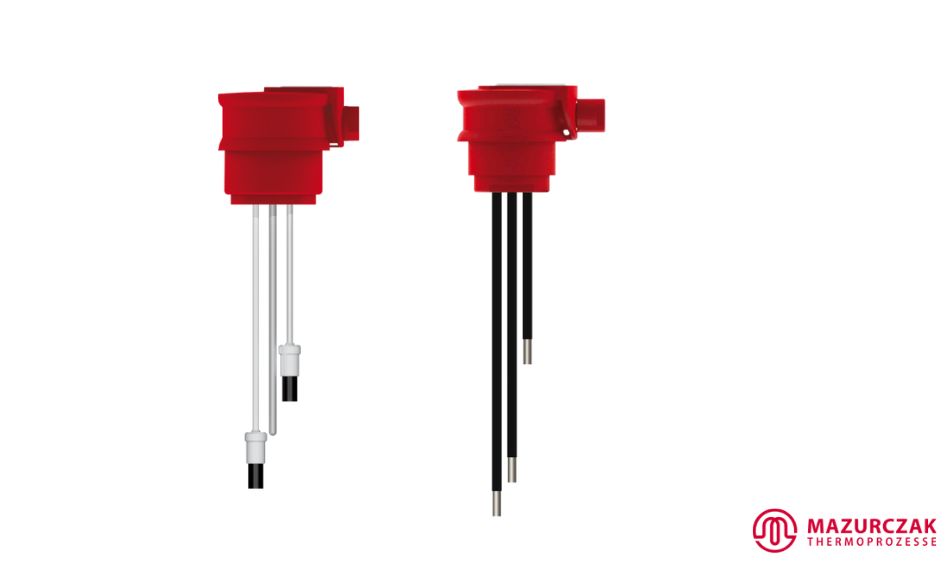

Conductive Level Probes NS/NT

You can implement safe control and monitoring of the liquid level in tanks with level rod-probes. Since these are purely passive devices, suitable electronic controllers are needed.

Level rod-probes operate on a conductive principle which means that they can be used only in electrically conductive liquids (conductivity > 2µS).

Sensors Electronics

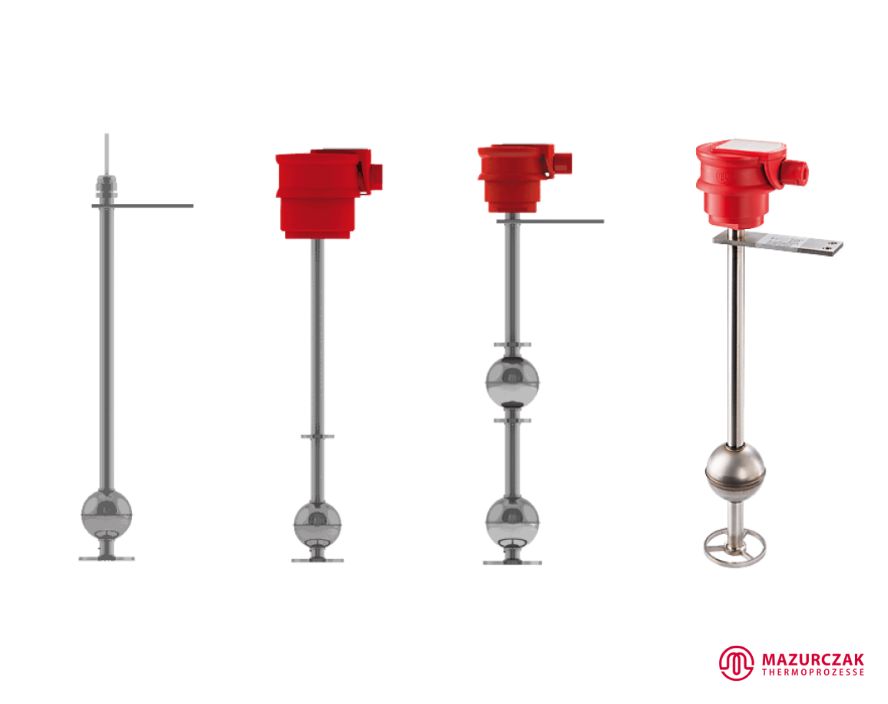

Level Switch-Stainless Steel

Float switches made from stainless steel offer a simple and economical solution for the controlling and monitoring of liquid levels in tanks.The float switches are available with one, two or three switch contacts and in various versions. Float switches can only be used in liquids which do not form encrustation; otherwise we recommend the use of our conductive level-rod-probes.

PG version On float switches without a terminal casing and with a permanently connected cable 1.6m long (other cable lengths to order), the cable is led out of the stainless steel tube of the float switch via a cable gland. Degree of protection IP 64 (splashproof) according to EN60529.

BC version The terminal casing BC (∅93mm), made of PP, permits connection of the cable and has the degree of protection IP 65 (jet waterproof) in accordance with EN60529. If the switch is exposed to high temperatures (liquid temperature >80°C), the PVDF terminal casing BC/L should be used. The cover can be unscrewed with the mounting wrench SB for access to cable terminals.

LC version The small terminal casing LC, made of PP or LC/L, made of PVDF, permits cable connection and has the degree of protection IP 65 (jet waterproof) in accordance with EN60529. The cover can be unscrewed with the mounting wrench SL

Sensors Electronics

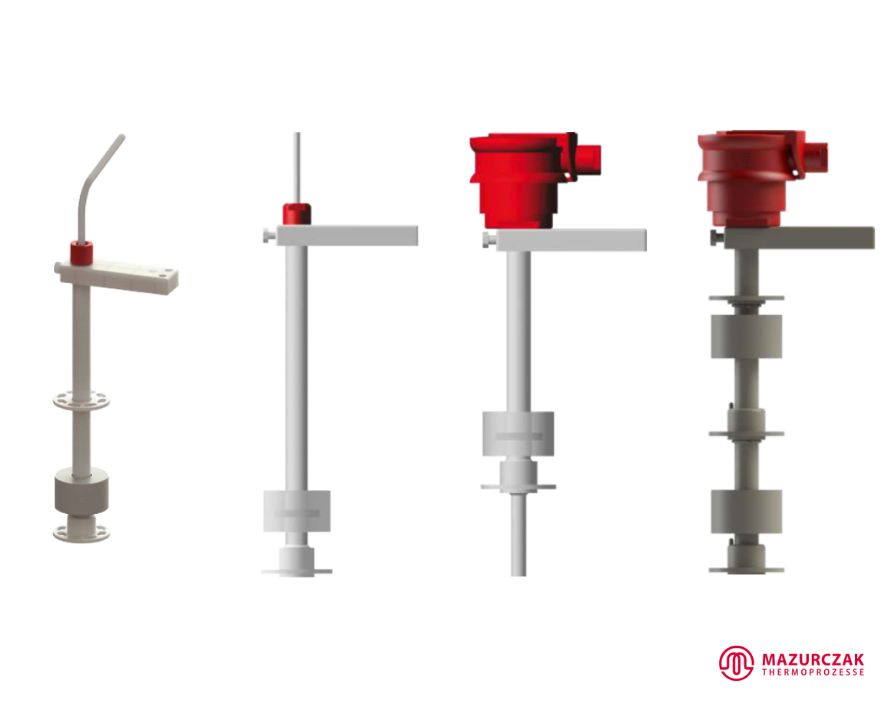

Level Switch-PP & PVDF

Float switches made from PP/ PVDF offer a simple and economical solution for the controlling and monitoring of liquid levels in tanks.

The float switches are available with one, two or three switch contacts and in various versions. Float switches can only be used in liquids which do not form encrustation; otherwise we recommend the use of our conductive level-rod-probes.

PG version On float switches without a terminal casing and with a permanently connected cable 1.6 m long (other cable lengths to order), the cable enters the tube of the float switch via a cable gland. Degree of protection IP 64 (splash-proof) according to EN 60529.

LC version The small terminal casing LC made of PP or LC/L made of PVDF permits cable connection and has the degree of protection IP65 (jet-waterproof) in accordance with EN60529. If the level switch is exposed to high temperatures (liquid temperature >80°C) or in contact with strong oxidizing chemicals (e.g. chrome electrolytes or HNO3 ) the PVDF terminal casing LC/L should be used

Sensors Electronics

Residual Current Monitor DSW 3/2

The differential current monitor DSW3/2 monitors the currents in the individual phases (L1, L2, L3) of a three-phase mains supply. When the limit value set for power consumption imbalance is exceeded, the power contactor is switched off via the relay contact. The limit value recommended for power consumption imbalance is 5.0%. The DSW3/2 differential current monitor reacts in the following situations:

- Overload protection (for current consumption monitoring)

- Current phase failure (if the temperature limiter in the immersion heater is activated)

- Current phase failure (if the heating coil fails or in case of cable breakage)

Sensors Electronics

Temprature Probes

With a temperature probe and a suitable electronic unit you can regulate and control the temperature of your liquids.

The temperature probes are equipped with Pt100 sensors. With the aid of temperature sensors and suitable electronic units, you can control and monitor the temperature of liquids easily and cheaply. Our temperature sensors are available in the following versions: • with rigid immersion tubes made of various materials • with flexible tube made of PFA

Sensors Electronics

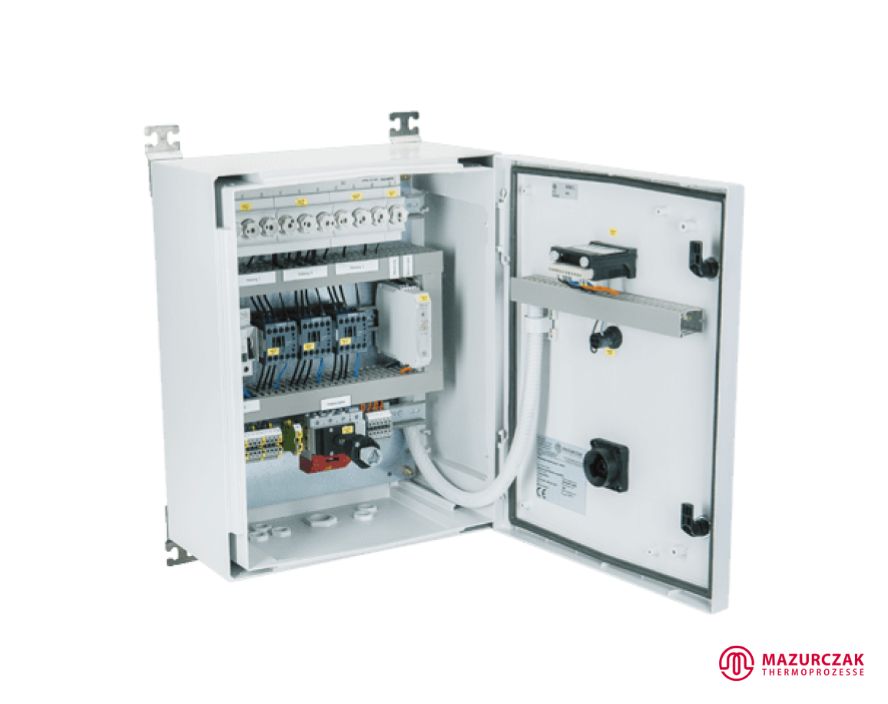

Compact Heating Control System KHS

In accordance with EN 60519 – 1/2 any electrically heated containermust be equipped with a thermostat and a level monitoring system. Itis, however, often not possible to integrate all necessary componentsinto a large control cabinet. Our solution – the Compact HeatingControl System KHS.All components necessary for the safe operation of the heating systemare contained in a light grey, glass fibre reinforced polyester enclosure(protection type IP 65 in accordance with EN 60529). The control cabinetcan be mounted with stainless steel mounting brackets onto a walldirectly next to the container.

Sensors Electronics

Electronic Fluid Level Control & Monitoring Equipment

The small level controllers with universal power supply (AC/DC) for cabinets monitor the liquid level of tanks.

Additionally to the universal power supply for AC/DC-connection, these controllers offer an easy and fast adaption of parameters to the application.

Sensors Electronics

Temprature Limiter ETB 200

The ETB200 temperature limiter monitors the temperature of process liquids in systems to a set limit value. If this value is exceeded, the integrated relay (AC230 / 2A with fuse) switches to a safe operating state and the backlighting of the LC display changes from white to red.

The temperature sensor approved by TÜV in compliance with DINEN14597, in combination with our certified TF 24 – 160/ SMG00 -M temperature sensor, represents a standards-compliant temperature limitation system. The electronics have been tested for electromagnetic compatibility in accordance with EN61326 and provide functional safety conforming to SIL 2 in accordance with EN61508. The Pt100 sensor element in 4-conductor technology is located in a flexible protective tube made from the fluoropolymer PFA with a diameter of 6mm and a nominal length of 1.6m. The small MG00 plastic housing (protection rating IP64) at the end of the PFA protective tube permits problem-free connection of a line. The maximum usage temperature of the temperature sensor is 200°C.

Sensors Electronics

Electronic Temprature Controler MTR

The temperature controllers MTR 1000/1020/2000 are especially designed for the rough operating conditions in surface treatment plants.

The temperature controllers are designed for installation on control panels. The front protection class is IP 65.